Ergono3D

Personalized Insole Design, Print-Ready STL in Minutes

7 followers

Personalized Insole Design, Print-Ready STL in Minutes

7 followers

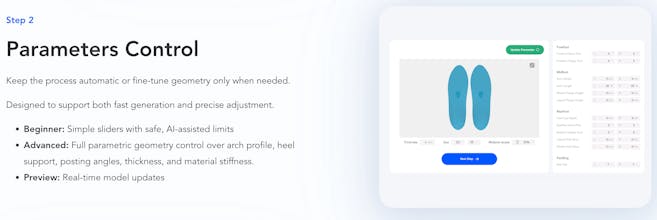

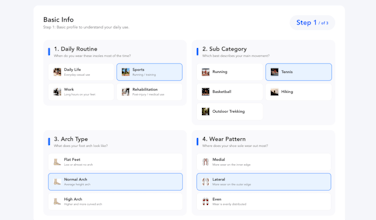

Ergono3D, a healthcare MCP platform, is a browser-based custom insole design generator. By replacing technical CAD work with simple inputs like use case and foot parameters, users simply select their use case and enter basic foot measurements—no CAD or manual modeling required. Makers, athletes, and clinicians can generate parametric designs and export 3D-print-ready STL files in minutes on Ergono3d.com

This is such a killer use case for 3D printing. 🚀

I’ve actually tried modeling my own orthotics before, and honestly, getting those organic curves right in CAD without professional tools is a total nightmare. It’s crazy that until now the options were basically 'cheap drugstore foam' or 'pay a specialist $400.'

Really curious about the posting preference you mentioned—is the engine actually adjusting the internal lattice density to create that support, or is it mostly just changing the external geometry?

Also, for the print itself, is the algorithm tuned for standard 95A TPU? I'd love to know if I can get away with stiffer/softer filaments and still get the right biomechanical response.

Super excited to test this out. The ability to print, wear it for a day, and then tweak the fit for just $2 of filament is a huge unlock.

As a heavy guy with flat feet I have crushed every insole I tried to print myself. Standard gyroids just collapse under 200lbs unless I spend hours tweaking density settings.

Does your algorithm account for user weight to automatically reinforce the lattice? If you solved the physics so I do not have to manually engineer the durability that is a huge value add.